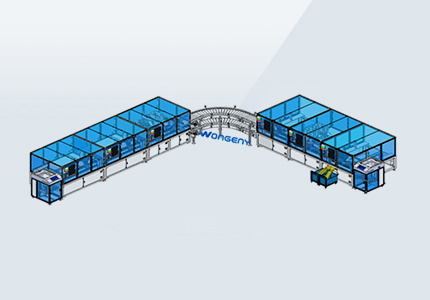

Automatically achieve product filling, sealing, capping, labelling, sorting and discharging. And at the core process of product inspection; can fill acidic, alkaline, alcohol, turbid liquid, low temperature liquid, high viscosity silicone oil and paraffin wax; can be turbid liquid with special treatment to ensure that the liquid inside to maintain uniformity. The modular design of the line facilitates flexible combinations according to process requirements. Compact: 7 kinds of liquid filling, 6 kinds of material assembly, occupies an area of less than 9 square metres, High efficiency: 1000~1500pcs per hour (standard capacity), High precision: high viscosity and micro-liquid filling within 2% accuracy, Reliable: the line body can achieve filling and assembly self-checking, to ensure that the production process is in compliance with the standard.

・Applicable products: acidic, soda,alcohols, suspended liquids, low-temperature liquids, high viscosity silicone oil, paraffin and other reagents.

・Functions: automatic filling, sealing, capping, labeling, and classification unloading of reagents.

・Production capacity:1000-3600pcs/line/hour (or configured accordingto customer demands)

・Number of operator: 1.

・Flexibility: modular design; There are two optional modes to be selectedsemi-automatic or fully automatic.

・Accuracy: complete filling of high viscosity and trace liquids within 2% accuracy. Special treatment can be applied to suspended liquids to ensure uniformity inside the liquid.